தயாரிப்பு விளக்கம்

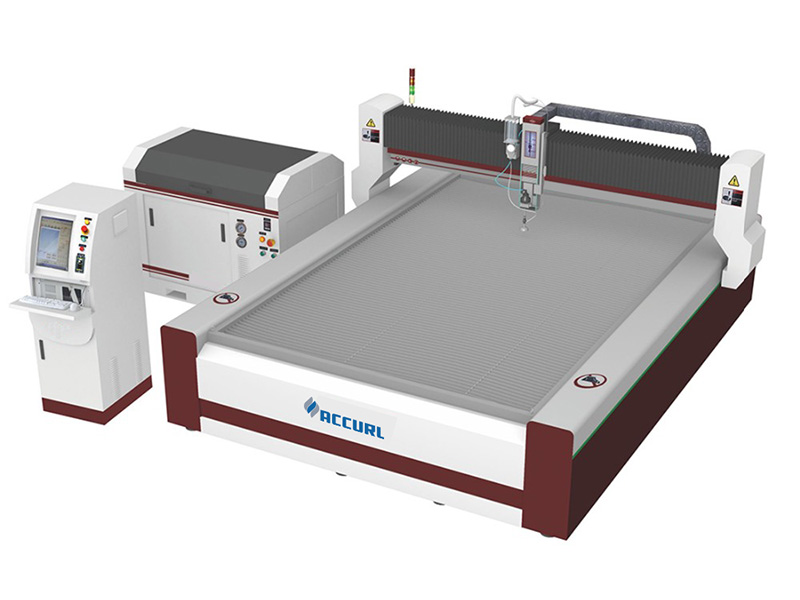

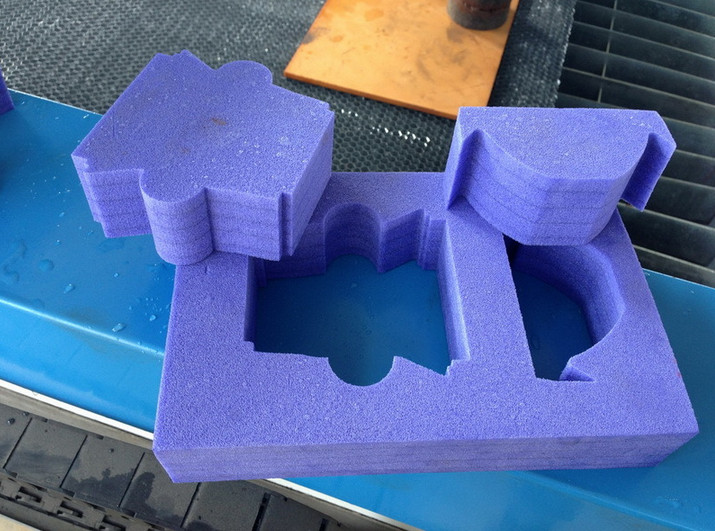

420MPA 3-Axis Pure Waterjet Cutting machine for foam , leather , plastic film

1.The beam is an extrusion molding piece of aluminium alloy.lightweight, High-rigid, stable running and faster speed.

2.Integral design,which has advantages of good rigidity and stability, uniform stress, stable running and precision.

3.Special shield design,waterproof and dust proof.

4.Bearing platform gratings adopts S-type, nets and straight line design,Which can be chose according to 5.different requirements , has strong practicability and can be durable in use.

6.There are adusting nuts on the bearing platform to regulate the flatness.

7.Imported servo driver, accurate localization, stable running, to ensure machining precision.

8.Safety protection:overtravel range limit protect function.

9.Taiwan TBI Lead Screw(imported) guarantees high precision of parts processing, non-clearance movement.

10The Taiwan Silver Guide Rail guarantees high precision of parts processing,smooth transmission, and durable in use.

11. Large split type gantry adopts separate rack, helical pinion and rack have the advantages of good rigidity, high precision, more stable running, unlimited length, high cutting efficiency, and no effect on precision and cutting quality.

Cantilever type NC cutting platform can install and discharge workpieces from three directions, which overcome the gantry's drawbacks, such as , loading material can only from both sides and work pieces' size are limited .it is practical for cantilever machine to place materials larger than the platform.

The running mechanism detached from cutting platform and have no effect on each other, the space of up-down material is larger, especially suitable for the Irregular material size and the situation which means of up-down materials is not fixed.

Cutting platform technical parameters

Power source: 220/380/415V AC,50/60HZ

X-Axis Max.speed: 6000mm/min

Y-Axis Max.speed: 6000mm/min

Z-Axis Max.speed: 1000mm/min

Control precision: ±0.02mm

Cut precision: ±0.1~±0.2 subject to speed and thickness of materials.

Resetting precision: ±0.02

Drive system JAPANESE YASKAWA

TAIWAN DONG YUAN AC servo system.

Cantilever system model

| Model. | X-axis route mm | Y-axis route mm | Z-axis route mm |

| HSQ0505U | 500 | 500 | 150-200 |

| HSQ1010U | 1000 | 1000 | 150-200 |

| HSQ1210U | 1000 | 1200 | 150-200 |

| HSQ1313U | 1300 | 1300 | 150-200 |

| HSQ2015U | 1500 | 2000 | 150-200 |

| HSQ2515U | 1500 | 2500 | 150-200 |

| HSQ2520U | 2000 | 2500 | 150-200 |

| HSQ3015U | 1500 | 3000 | 150-200 |

| HSQ3018U | 1800 | 3000 | 150-200 |

| HSQ4015U | 1500 | 4000 | 150-200 |

| HSQ4018U | 1800 | 4000 | 150-200 |

| HSQ4020U | 2000 | 4000 | 150-200 |

| HSQ5020U | 2000 | 5000 | 150-200 |

| HSQ6020U | 2000 | 6000 | 150-200 |

| HSQ8020U | 2000 | 8000 | 150-200 |

| HSQ9020U | 2000 | 9000 | 150-200 |

| HSQ10020U | 3000 | 10000 | 150-200 |

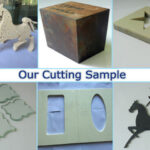

பயன்பாடுகள்:

சி.என்.சி வாட்டர் ஜெட் கட்டிங் மெஷின் can flexibly process (cut off, engrave, make hole, drill) virtually all materials with consistent quality. It has found great application in metal, glass, stone, chemical & petroleum, automotive, advertisement and other industries.

Price & Delivery:

FOB Shanghai: price range 27,000-100,000 USD, which is subject to our final confirmation.

MOQ: 1 set

Term of Payment: T/T 30% deposit; T/T70% against B/L copy.

Term of Shipment: by sea with 20 ft standard container

பிராண்ட் பெயர்: ACCURL

உத்தரவாதம்: ஒரு வருடம்

Technician Support: Free field training and installation is available. Please contact us for details.

அடிப்படை தகவல்

Model NO.: HSQ2515U

Process Usage: Nonmetal Cutting

Control Method: Closed-Loop Control

Performance Classification: High-End CNC Machine Tools

நிபந்தனை: புதியது

Transport Package: Exported Standard Package

தோற்றம்: அன்ஹுய் சீனா

Application: Plastic, Leather, Wood

Movement Method: Contour Control

எண் கட்டுப்பாடு: சி.என்.சி / எம்.என்.சி.

சான்றிதழ்: CE, ISO 9001

வர்த்தக முத்திரை: ACCURL

விவரக்குறிப்பு: CE, ISO, SGS

HS Code: 84642010